Description & Specifications

|

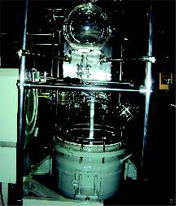

Reaction & Distillation Unit Reaction systems are developed to fulfill the actual needs of chemical and pharma industry. Sigma Reactors are built for batch and semi – batch operation mode, with perfectly matched components and quality materials. Conforming to GMP / FDA Guide lines and Explosion proof installations. Reactor Options : Glass Single Wall, Glass Double Wall, Glass Triple Wall Reactor, Glass Reactor with SS Jacket, Glass Lined Reactor with Glass top and Glass Lined Reactor. Operating Parameters Pressure Range : Full Vaccum up to 0.5 bar (g) Temperature Range : -80°C to +200°C Capacities : 5 L up to 500 L Installation Sites : R & D Lab, Pilot Plant, Kilo Lab, Production. Salient Features : GMP design Skid Mounted / Lab - Hood Adaptability Documentation Instrumentation Safety Control Pure and corrosive Media Handling Safe operation Customized Reactor System-for up scaling Excellent thermal Process Control Reactor Bottom Pan Single wall Round bottom Reactor up to 300L Single wall Cylindrical Reactor up to 500L Double wall Cylindrical Jacketed up to 200L Triple wall Reactor up to 50L Glass Lined Reactor (20L,50L,100L,250L), pre-insulated (with SS cladding) Glass Reactor with SS Jacket ( Pre insulated with SS cladding ). |